Se sei un marketer digitale, sicuramente sai che Google Ads è uno strumento potente per promuovere il tuo business online. Tuttavia, la gestione di una …

Scopri i diritti di proprietà intellettuale: tutto ciò che devi sapere

La proprietà intellettuale è un tema molto importante per molte aziende e imprenditori. Essa rappresenta il valore immateriale delle attività svolte, ovvero le idee, le …

Link Building: Guida Completa per una Strategia di SEO Off-Page Efficace

La Link Building (per maggiori informazioni in merito al servizio visita il sito https://www.spider-link.it) è un’attività fondamentale per migliorare la visibilità di un sito web …

Come sbiancare le tende sintetiche: una guida semplice ed efficace!

Le tende sintetiche sono una scelta pratica e conveniente per molti proprietari di case. Sono facili da pulire e resistenti all’uso, ma possono perdere la …

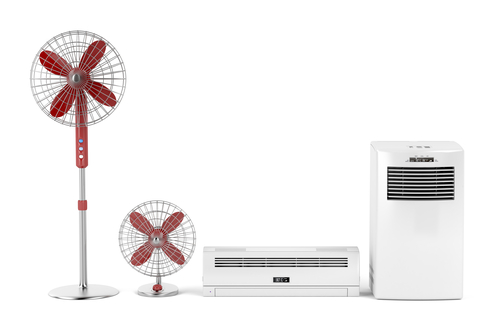

Vantaggi e caratteristiche dei climatizzatori portatili

Per ovviare alle temperature eccessivamente alte nel periodo estivo e creare aria fresca in casa, è necessario dotarsi di un condizionatore portatile. Una soluzione ottimale …

Chi abita al piano terra deve pagare l’ascensore?

Ascensore in condominio: chi abita al piano terra deve pagare l’ascensore? Una delle problematiche che si configura frequentemente quando si fà riferimento ad un condominio …

Installazione ascensore in condominio: costi e informazioni

Abiti in un condominio, ti sei appena trasferito e non sai nulla sui costi e la manutenzione dell’ascensore di condominio? Hai paura di fare gaffes …

Come lavare le tende in maniera ottimale

Sapere come lavare le tende può essere molto utile per coloro che hanno intenzione di garantire al proprio ambiente una protezione ottimale dai raggi e …

Piante da siepi sempreverdi resistenti al freddo e al caldo

Le piante da siepi sempreverdi: funzionali, resistenti e decorative L’utilità delle piante da siepe in un giardino concorrono a regalare un aspetto curato e rigoglioso …

Come funziona antifurto casa senza fili?

Casa propria è per antonomasia il luogo dove ci si sente più al sicuro. Tuttavia, anche le abitazioni che apparentemente risultano inviolabili, corrono il rischio …

Come utilizzare i pallet per arredare casa?

Usare i pallet per arredare la casa: idee e consigli Arredare una nuova casa o completare quella già esistente è una sfida eccitante e al …

Come usare il condizionatore in inverno

La diffusione dei condizionatori all’interno delle proprie mura domestiche, complice il rapido progresso tecnologico e il cambiamento climatico, che costringe ad adattarsi ai nuovi climi …